GURIT – STRUCTURAL CORE

GURIT – STRUCTURAL CORE

Gurit is a leading global manufacturer of advanced composite materials, Gurit integrates structural design, materials science and process engineering to offer a complete turnkey composite solution, Gurit is specialised in the development and manufacture of advanced composite materials.

The comprehensive product range comprises fibre reinforced prepregs, structural core products, process coats, adhesives and laminating resins, Gurit supplies global growth markets with composite materials, composite tooling equipment, core material wind turbine blade kits and structural engineering.

Gurit covers a wide range of Industrial Business Units, providing a comprehensive range of structural core products, formulated and prepreg materials.

GURIT:

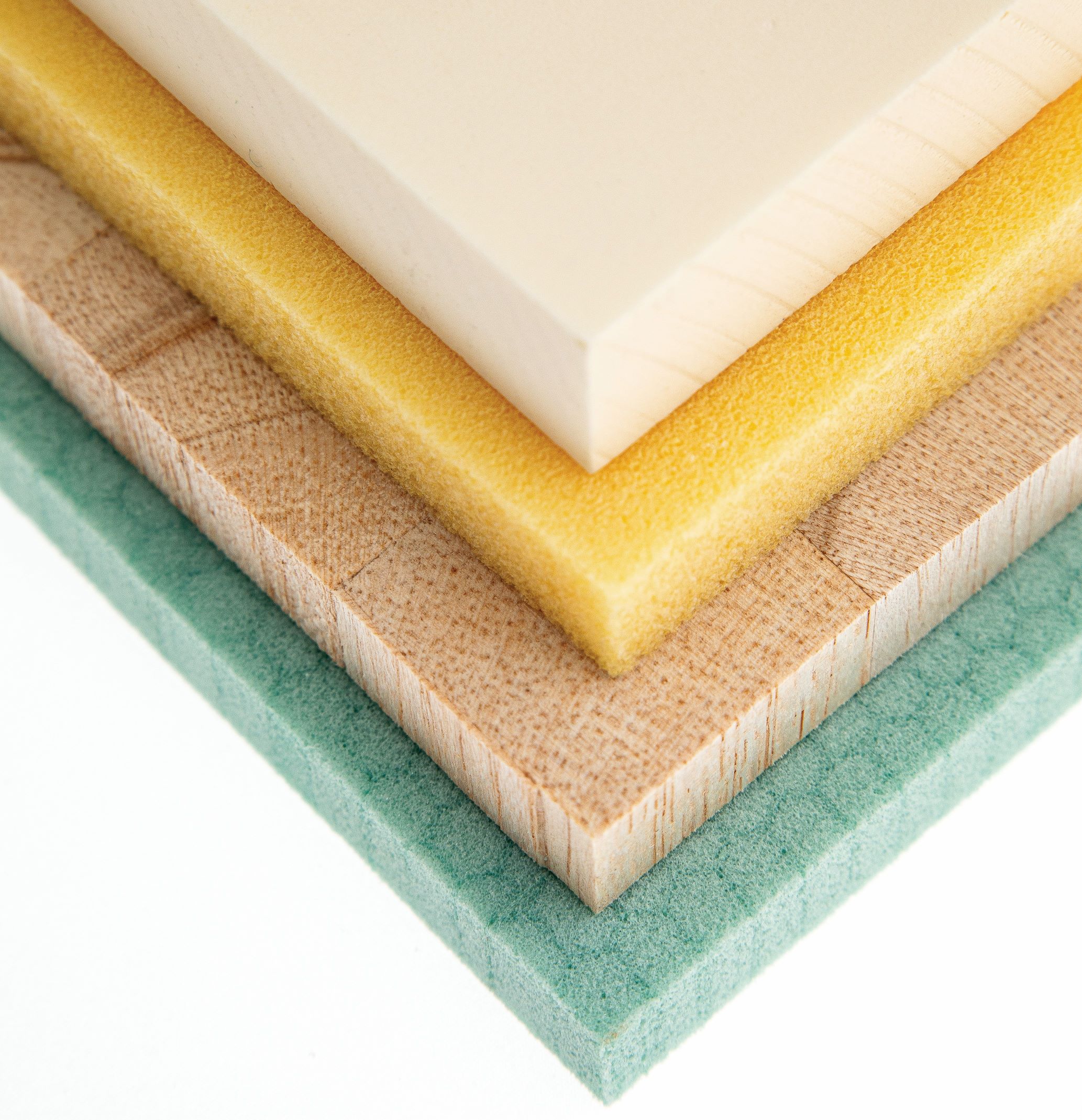

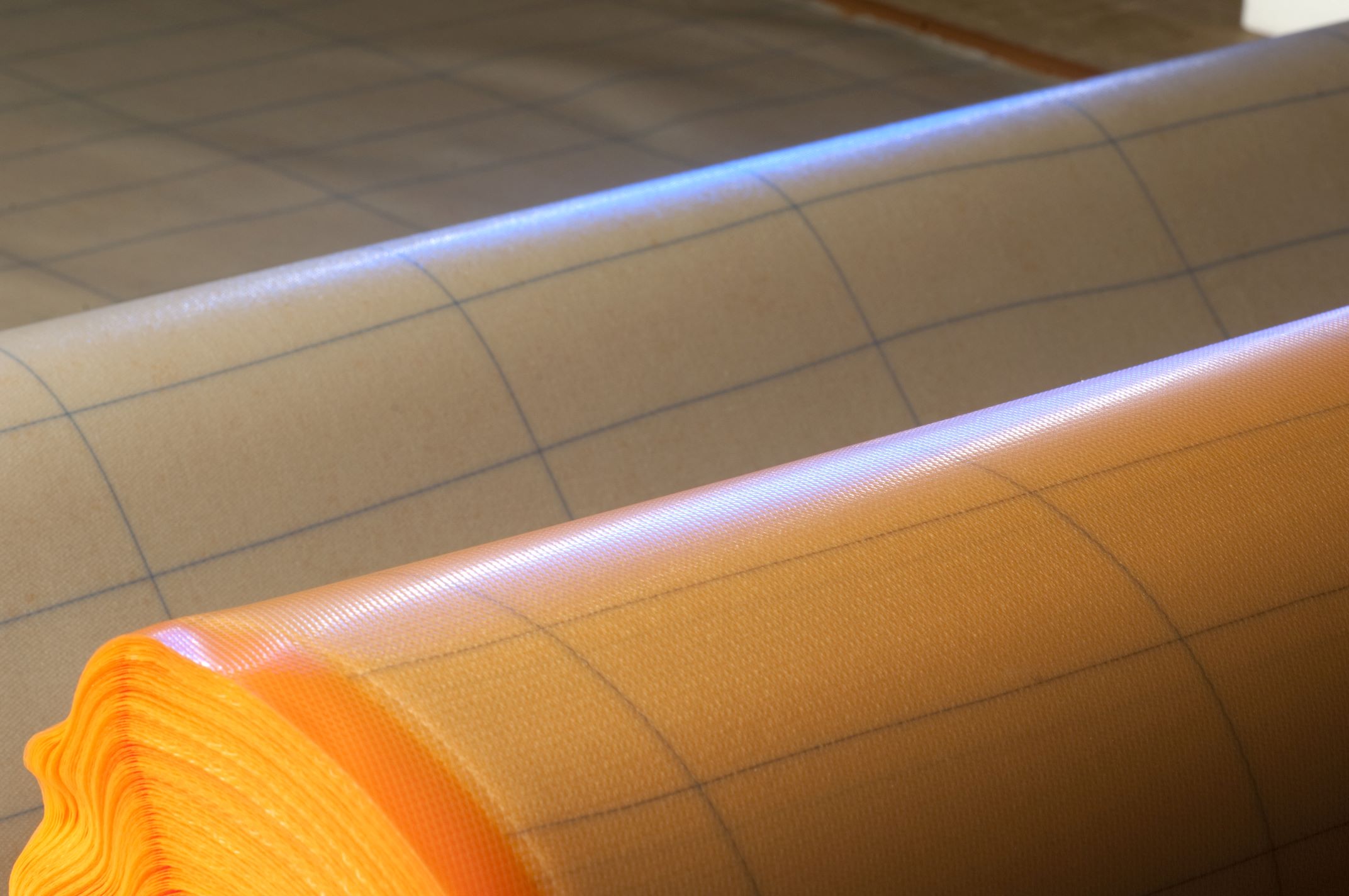

STRUCTRUAL CORE MATERIALS: Gurit is a technical leader in the development and manufacture of structural core materials. Cores in a sandwich construction are specified by designers and architects to increase stiffness and reduce the weight of a composite structure. Gurit has a range of core materials to fit any specification or manufacturing process.

https://www.gurit.com/structural-core-materials/

EPOXY RESINS & ADHESIVES: Gurit is a leading supplier of high performance epoxy products formulated to meet market and customer needs. Our innovative approach and expertise in epoxy formulations continues to deliver market leading products for a wide range of market segments. We provide a complete range of formulated products including adhesives, in-mould gelcoats, laminating and multi-purpose systems.

https://www.gurit.com/epoxy-resins-adhesives/

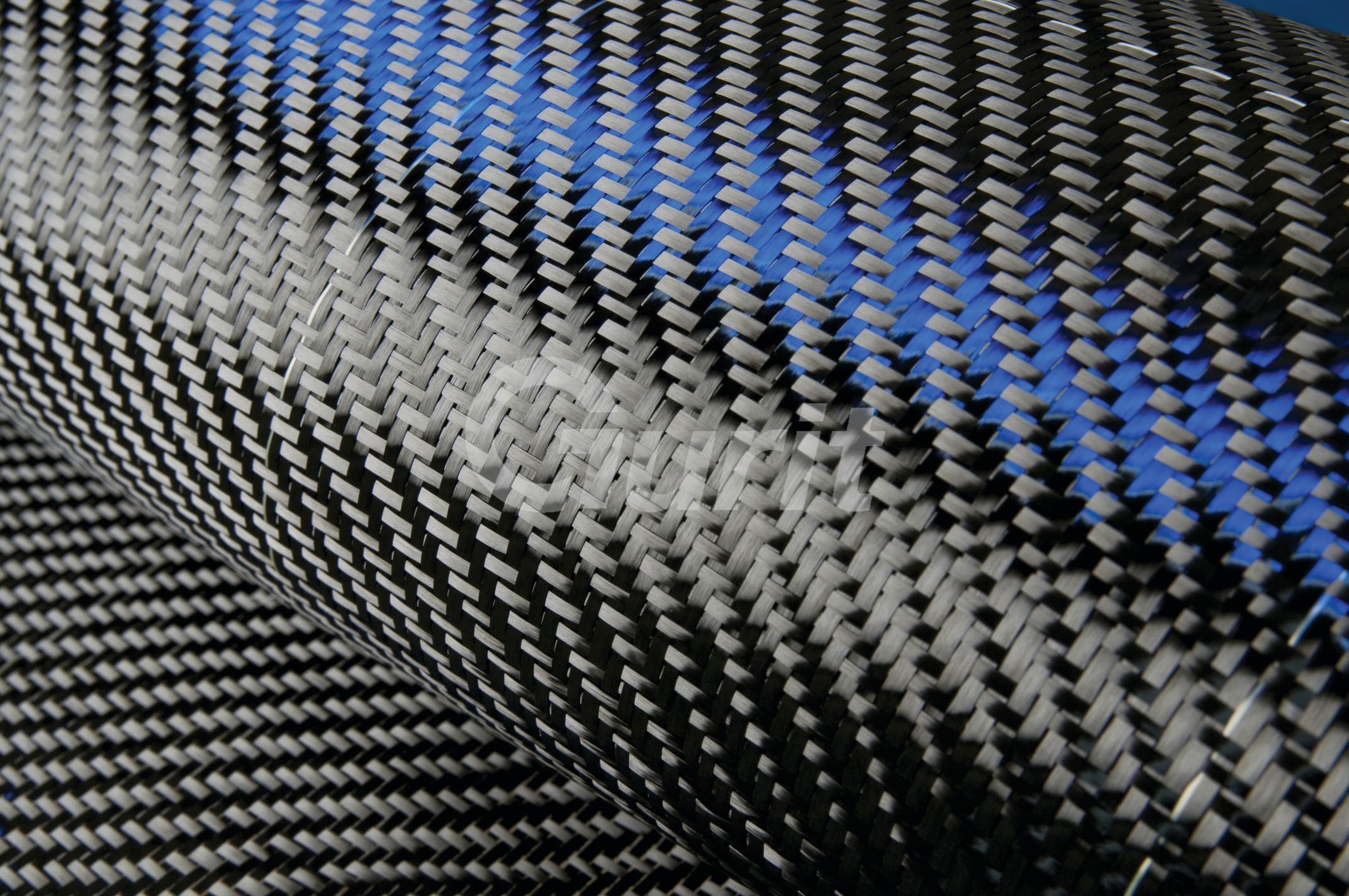

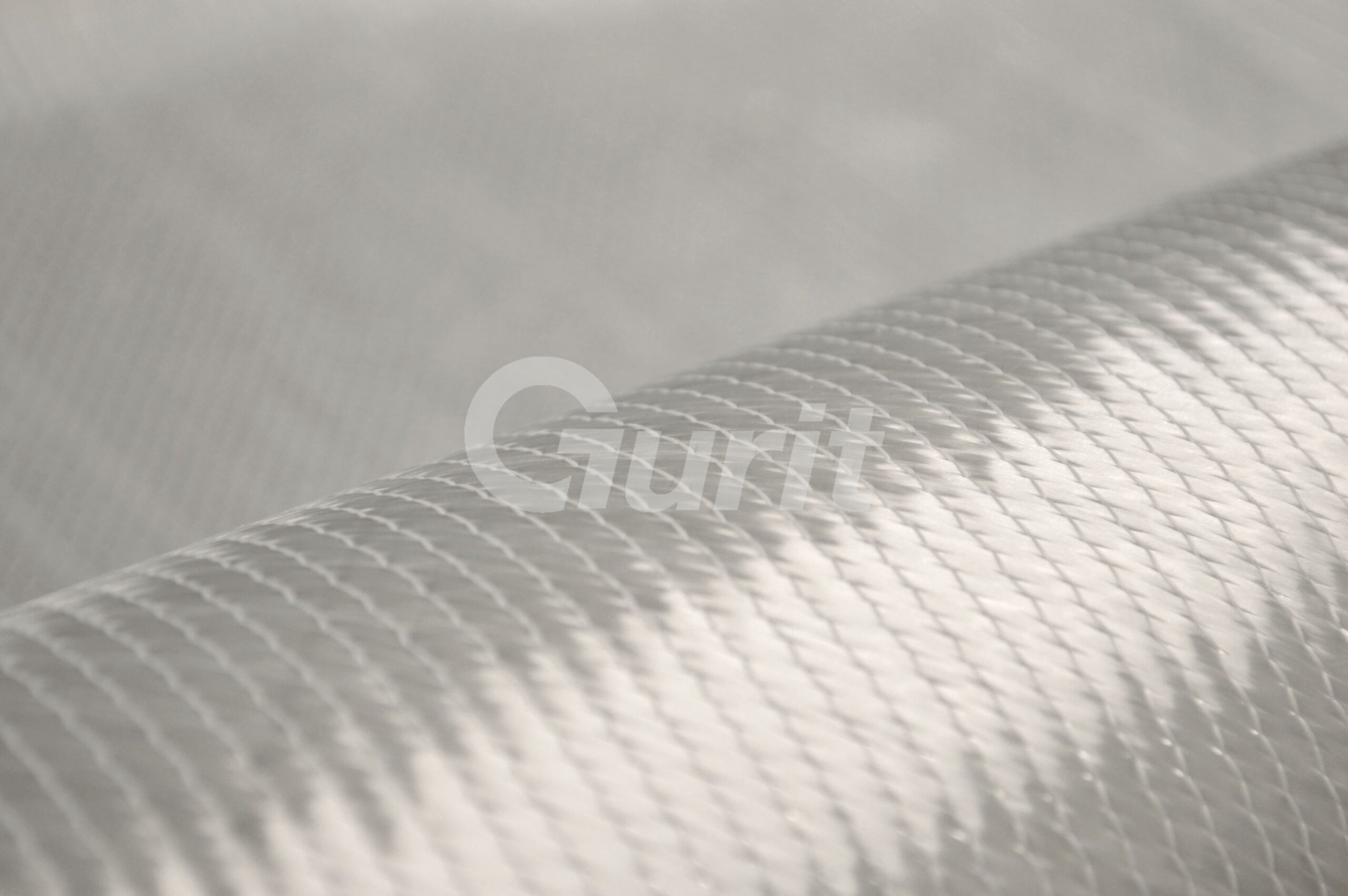

PREPREGS & SPRINTS: Pre-impregnated materials (prepregs) are reinforcement fibres or fabrics into which a pre-catalysed resin system has been impregnated by a machine. The resin systems in these materials react very slowly at room temperature, giving rise to working times of many days or months. Prepreg resins can only be fully cured by heating them to the prescribed cure temperature. The accuracy of the machinery used to combine the fabric or fibre with the resin ensures that laminates produced from prepregs have more consistent and higher fibre contents than can be achieved by wet lay-up techniques. This allows the use of very tough, strong resin systems that would be too high in viscosity to be impregnated by hand.

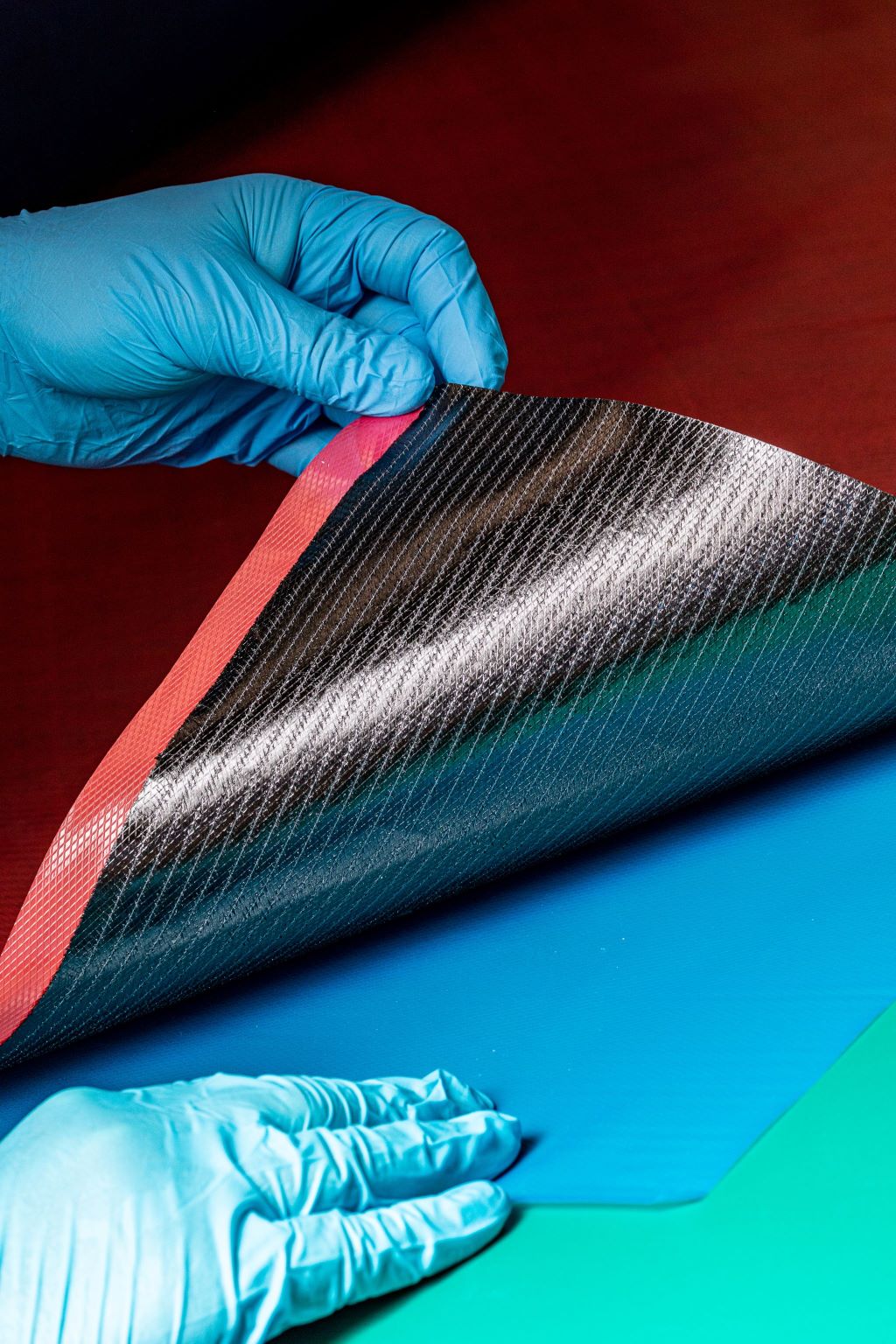

SPRINT™ materials consist of 1 or 2 layers of fibre reinforcement combined with a pre-cast, pre-catalysed resin film. The material therefore has the appearance of dry reinforcement, which has resin concealed at its centre. SPRINT™ materials are produced by a process that differs from conventional prepreg so that the fibres in the reinforcements remain dry and un-impregnated by the resin. SPRINT™ materials are laid up in a mould and vacuum bagged as for conventional prepreg. However, when the vacuum is applied, the air transport properties of the dry reinforcement enable air trapped in the fibre bundles and between layers to be easily removed. When the temperature is then raised for the cure, the resin film softens and flows into the air-free reinforcement. The void content of the resultant laminate is extremely low (typically 0-0.5%).

https://www.gurit.com/prepregs

ANCILLARY PRODUCTS: To support the use of materials manufactured and supplied by Gurit, a comprehensive range of Ancillary Products is also available. These have been refined over many years to enable users to handle products safely and to obtain the very best results from Gurit materials.

GURIT COMPOSITE ENGINEERING: Gurit Composite Engineering provides independent services within the field of Structural Engineering for Fibre Reinforced Polymers (FRP) and Carbon Fiber Reinforced Polymers (CFRP).