AIRTECH – VACUUME BAGGING

AIRTECH – VACUUME BAGGING

Airtech Advanced Materials Group, the largest manufacturer of vacuum bagging and composite tooling materials for prepreg, autoclave, resin infusion, and wet lay-up processes.

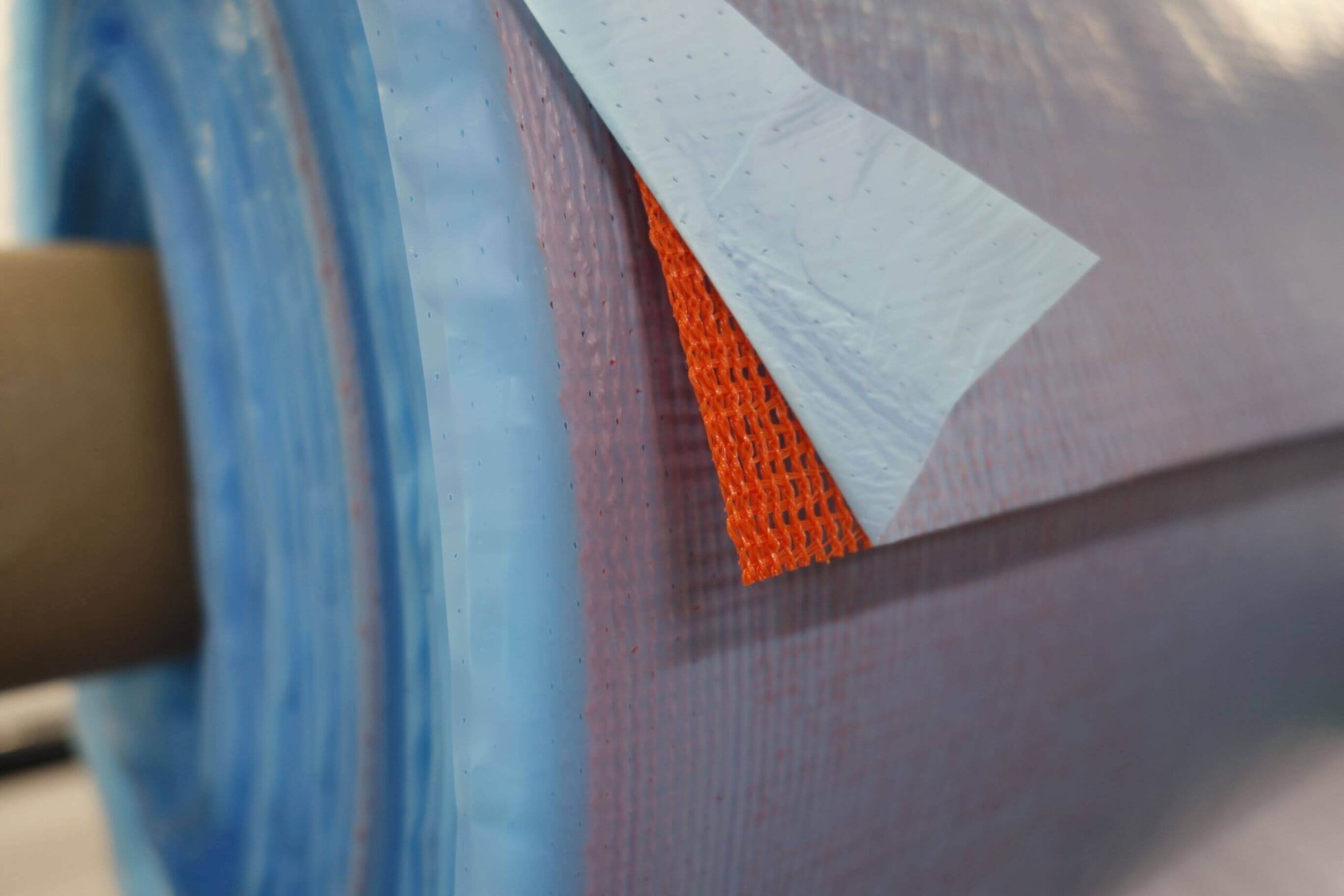

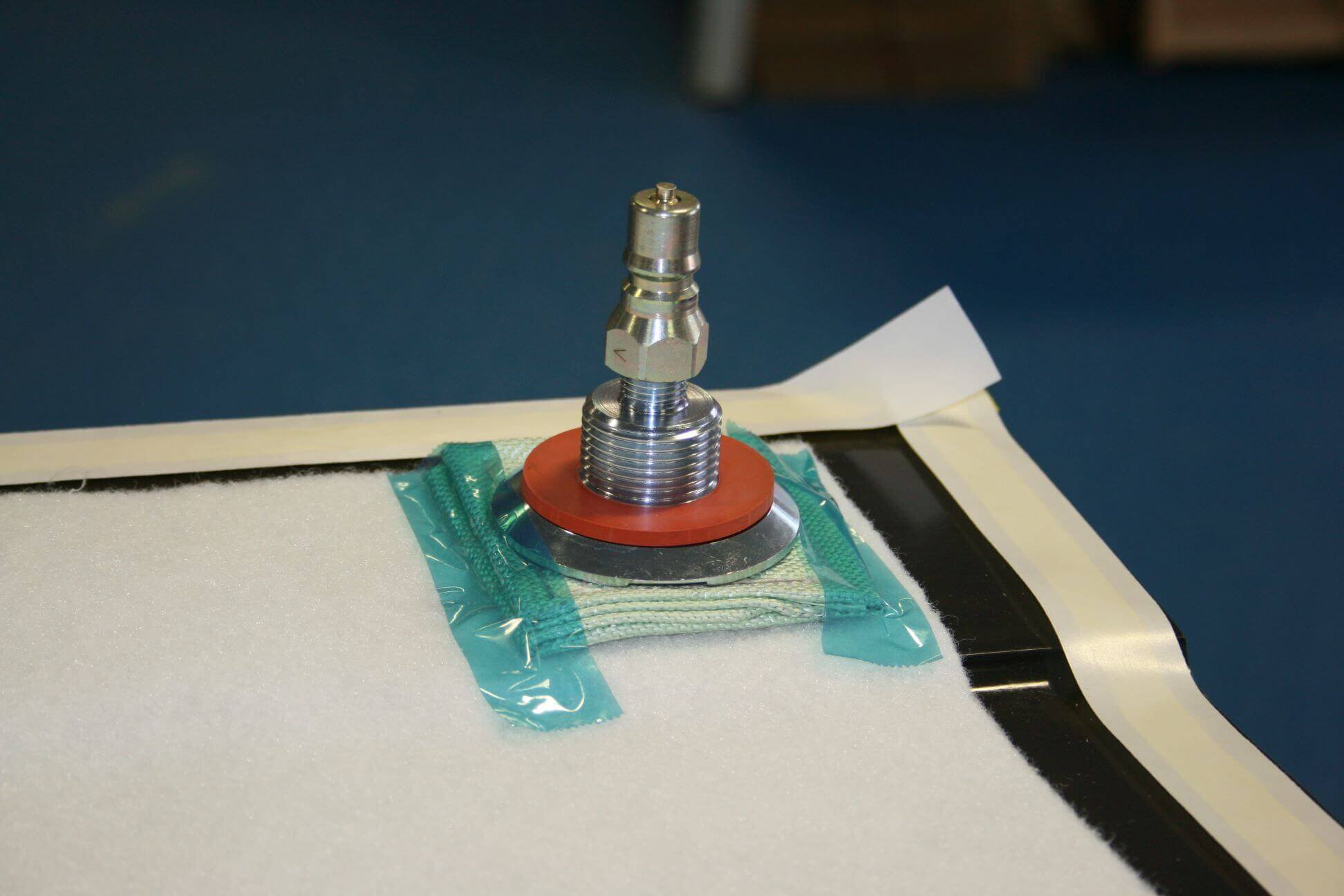

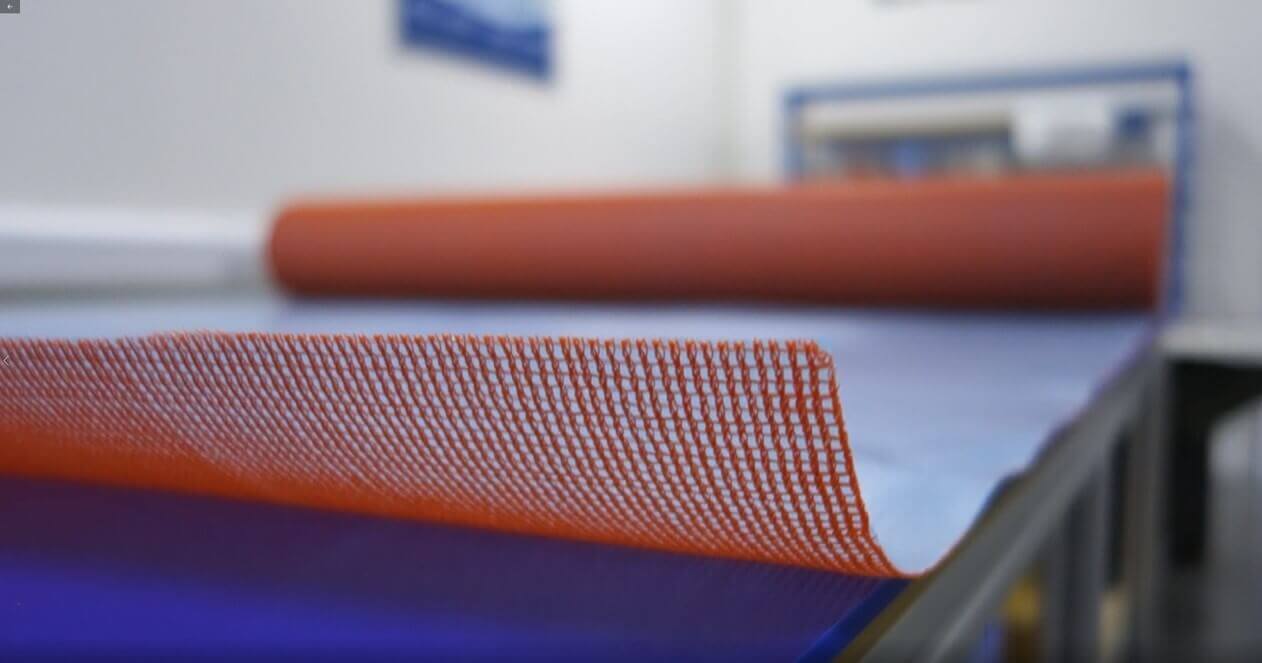

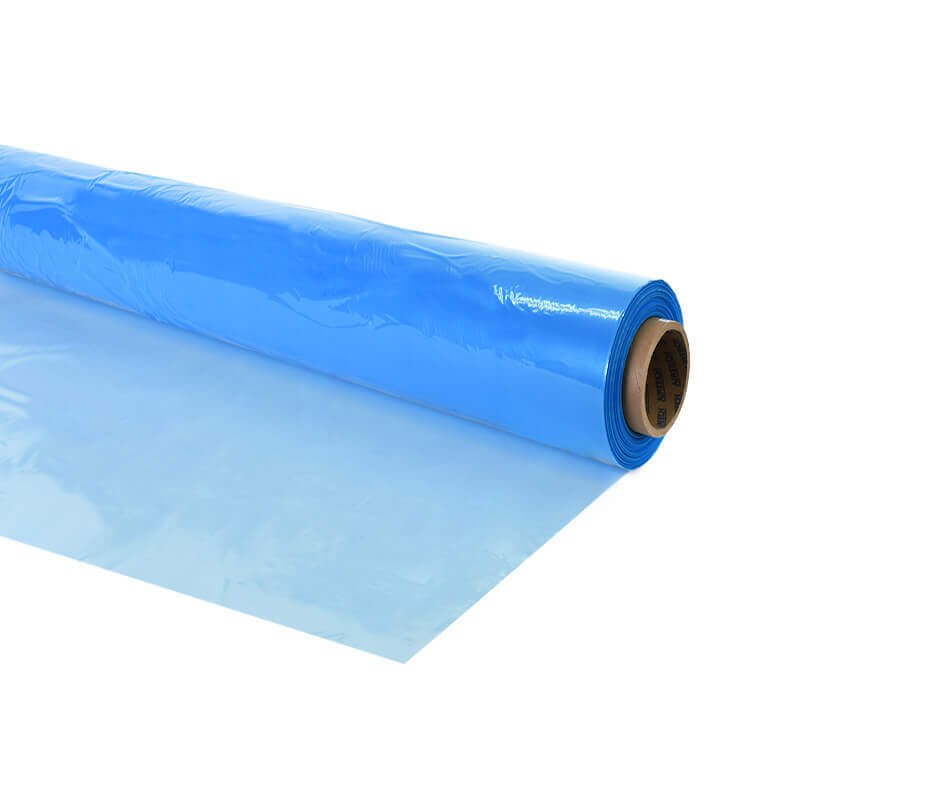

Product line consists of vacuum bagging films , release films, pressure sensitive tapes, mold releases (non-liquid), peel plies, breathers & bleeders, sealant tapes, vacuum bag connectors & hoses, rubber, pressure pads, cutting tools, vacuum leak detectors, shrink tape, PTFE coated fiberglass, tooling prepregs and resins, and carbon and glass reinforcements.

Business focus areas include aerospace, wind energy, marine, automotive, printed circuit board, solar energy and general FRP composites.

AIRTECH

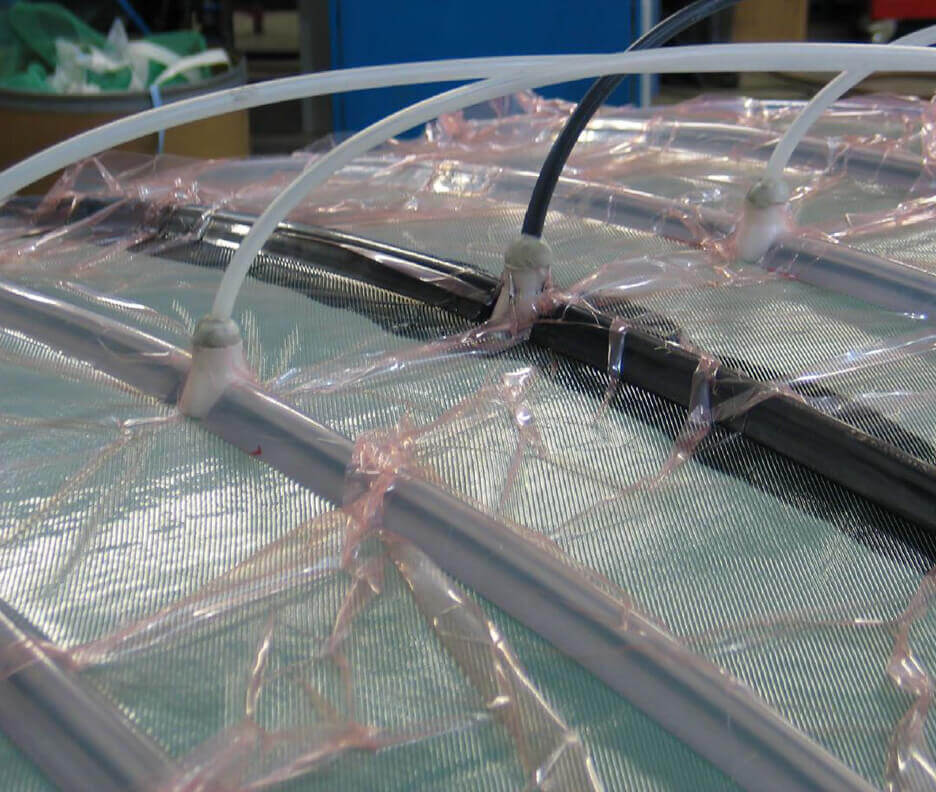

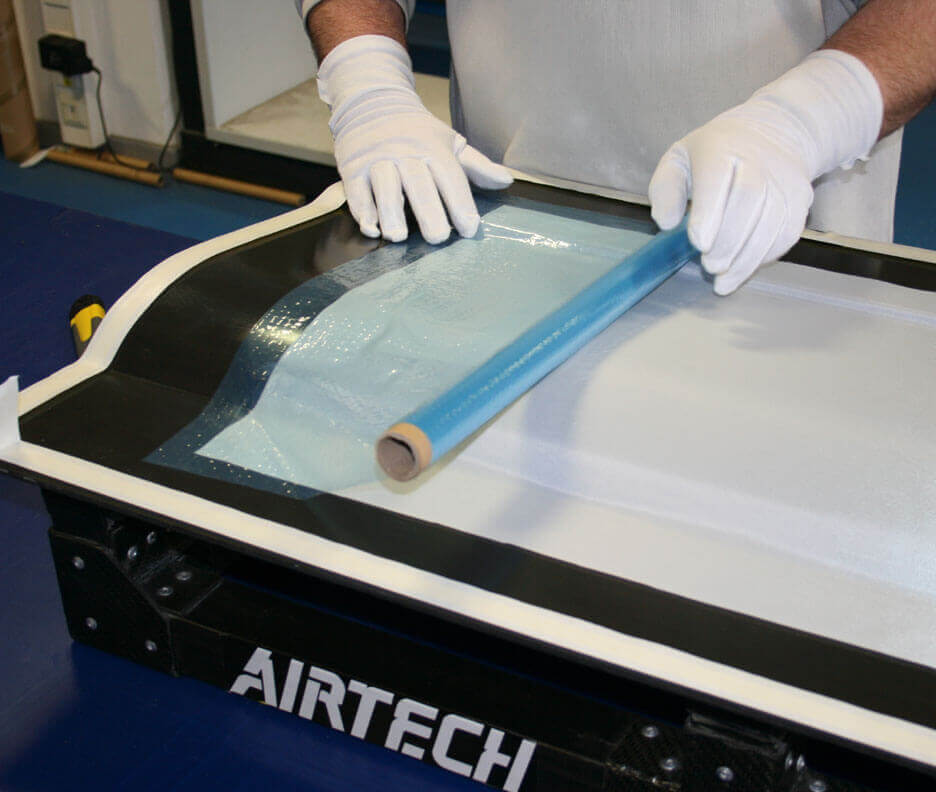

RESIN INFUSION PROCESS: Resin Infusion is a process by which vacuum draws resin into a dry fiber laminate in a one sided mold. A rigid or flexible film membrane is placed over the top and sealed around the mold periphery. Resin infusion is considered a “Closed Mold Process”.

https://airtechintl.com/resin-infusion

GLASS LAMINATING: The vacuum bagging process is employed in glass laminating to apply even pressure during bonding. Vacuum bags apply even pressure up to atmospheric pressure, 14.7 lbs. per square inch (2,000 lbs. per square foot). This predictable and consistent pressure application consolidates laminates.

https://airtechintl.com/glass-laminating

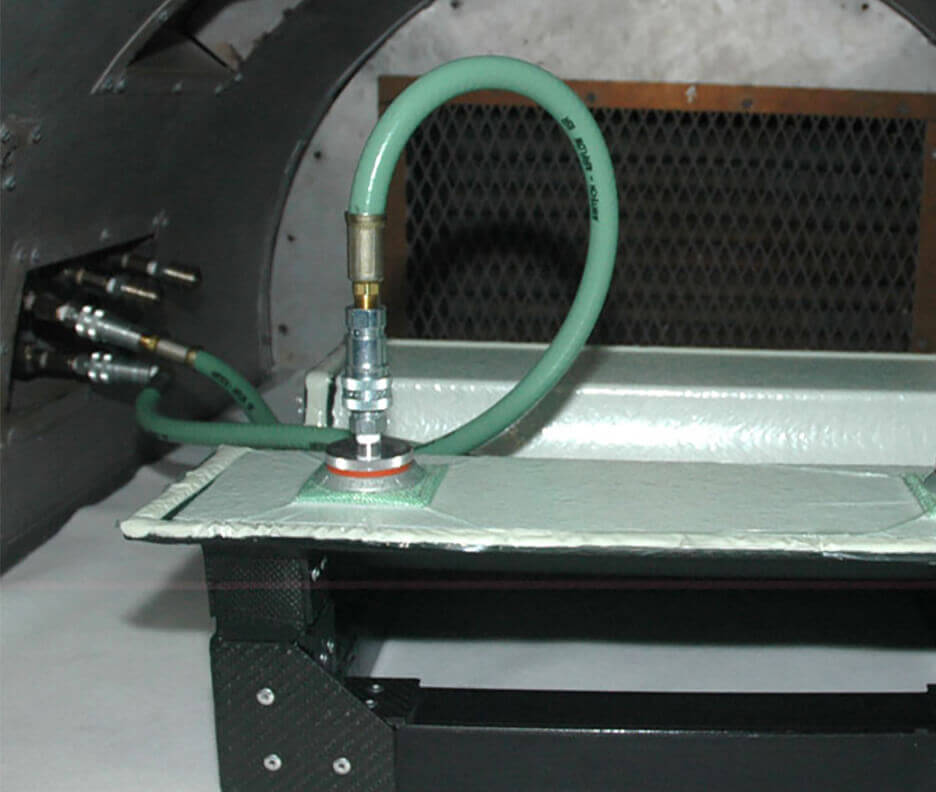

PREPREG / AUTOCLAVE: The moulding of pre-impregnated fabrics and film infused fabrics typically requires the use of elevated temperatures and vacuum consolidation under a vacuum bag in either Oven or Autoclave.